For many business owners, the transition to a low-carbon economy conjures images of rooftop solar panels and EV fleets. While these measures are beneficial, the implementation of low-cost energy efficiency and conservation strategies is the first and the most important step for a business wishing to reduce their energy costs and carbon footprint.

Stephen Dixon of KnowEnergy has spent 44 years working with organizations across Canada to improve their energy management strategies, starting with inexpensive solutions.

As an instructor for the Canadian Institute of Energy Training, Dixon promotes a three-pronged approach to tackling energy waste: implement technical measures, refocus organizational strategies to prioritize energy efficiency, and provide behaviour change support.

Implementing low-cost technical measures

Since heating and cooling are a major energy cost for most businesses, installing a programmable or smart thermostat is a great place to start. Smart thermostats can be scheduled according to occupational needs, with temperatures set back when a building is empty. This discourages haphazard, reactionary, and costly manual adjustments by staff.

Instead of allowing manual adjustments, organizations can encourage employees to report comfort concerns, then investigate and address the spaces that are too hot or too cold. This will result in both improved employee well-being and a reduction in unnecessary costs, including those associated with expensive-to-operate space heaters.

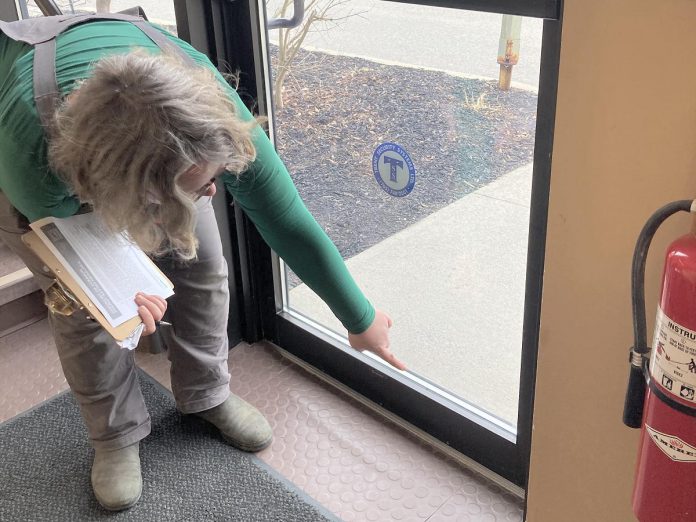

The efficiency of a heating system can also be improved with caulking, weather stripping, and inserting threshold seal strips and sweeps around windows and doors. During a cold winter or hot summer, energy loss from leakage can add up significantly.

If there is a section of a building where doors to the outside are frequently opened or must stay open, these should be sectioned off so that they are separate from areas with temperature-controlled air.

In the case of loading bay, a source of great energy loss, amendments like dock sealing, dock shelters, and dock plate sealers are beneficial, as are high-speed door closers which encourage greater staff use. Bay doors should never be used for personal needs.

Regularly scheduled maintenance of HVAC systems, including cleaning or replacing filters and ensuring that dampers are positioned appropriately, will also result in savings over the long term and can help equipment last longer.

When it comes to lighting, the use of natural light both saves money and improves employee wellbeing. Sensors can adjust lighting levels according to occupancy and the level of natural light available. Replacing incandescent or fluorescent lightbulbs with LEDs is a big energy savings win.

The equipment used will depend on the nature of the business. As a general rule — whether you’re talking about computers and printers, air compressors, or machinery in a manufacturing setting — turning off the power to equipment when it isn’t in use will save money. In an office setting, smart power strips can ensure that equipment isn’t drawing “phantom” power when turned off.

Prioritizing organizational efficiency

Successful businesses prioritize continuous operational improvement. When a business gets serious about energy management, it means embedding an “energy attitude” into operations.

A dedicated energy manager, whose role it is to create and implement a strategic energy management plan, is the ideal solution for larger organizations.

But even in a smaller business, energy efficiency can be promoted as part of the culture. Some ways to do this include providing staff opportunities to share efficiency ideas, having an energy check-in as part of regular meetings, and assigning an employee to track energy bills, flag changes, and — importantly — communicate efficiency wins.

Building new habits

While you can implement technical measures and secure the commitment of the leadership, behaviour change is equally important.

“If I could do it all again, I would put a greater focus on behaviour change and making those energy-reducing actions and attitudes automatic,” says Dixon.

Businesses can operationalize habits by writing actions like turning off lights and equipment, closing blinds at night in the wintertime, and having staff report concerns about machinery or HVAC systems into their procedures.

Having friendly staff competitions and ensuring the leadership is modelling the desired behaviours can further help ensure success.

To achieve cost savings and reduce your energy impact, consider introducing the three-pronged approach to energy management: implement low-cost technical measures, nurture a culture of organizational efficiency, and support habit development.

Using energy is costly; actions to reduce it don’t have to be.

GreenUP’s Green Economy Peterborough (GEP) program works with business owners to understand and strategically implement actions to reduce climate impact and increase efficiency. To learn more about what GEP can do for your business, email jackie.donaldson@greenup.on.ca or visit www.greeneconomypeterborough.ca.